Authorized Reseller of

Authorized Reseller of

The Crane Pad Shop in Japan

Although crane pads are very well-known in Europe and North America, they has not yet been widely recognized in Japan. Determined to make these excellent products easily accessible in Japan market, a Daikyo Kenki Co., Ltd. group company, Abileco International Co., Ltd. has imported the products into Japan for the first time in 2018.

After using it for years inside the company, we are pleased to confirm that crane pads are more resilient, lighter, and easier to carry than the steel and aluminum plates that are typically used in Japan. In 2020, with several foreign trading firms, we came to an exclusive distributorship arrangement in Japan.

We specialize in outstanding, high quality crane pads. Made from ultra-high molecular weight polyethylene (UHMWPE), they are resistant to corrosion and water while also being durable and long-lasting. Our Crane Pads range includes products specifically designed for a wide range of equipment including access platforms and mobile plant like concrete pumps, through to modular mats and bespoke pads for mobile cranes and other heavy equipment.

Although crane pads are very well-known in Europe and North America, they has not yet been widely recognized in Japan. Determined to make these excellent products easily accessible in Japan market, a Daikyo Kenki Co., Ltd. group company, Abileco International Co., Ltd. has imported the products into Japan for the first time in 2018.

After using it for years inside the company, we are pleased to confirm that crane pads are more resilient, lighter, and easier to carry than the steel and aluminum plates that are typically used in Japan. In 2020, with several foreign trading firms, we came to an exclusive distributorship arrangement in Japan.

We specialize in outstanding, high quality crane pads. Made from ultra-high molecular weight polyethylene (UHMWPE), they are resistant to corrosion and water while also being durable and long-lasting. Our Crane Pads range includes products specifically designed for a wide range of equipment including access platforms and mobile plant like concrete pumps, through to modular mats and bespoke pads for mobile cranes and other heavy equipment.

For stable support of lifting equipment, mobile plants and vehicles

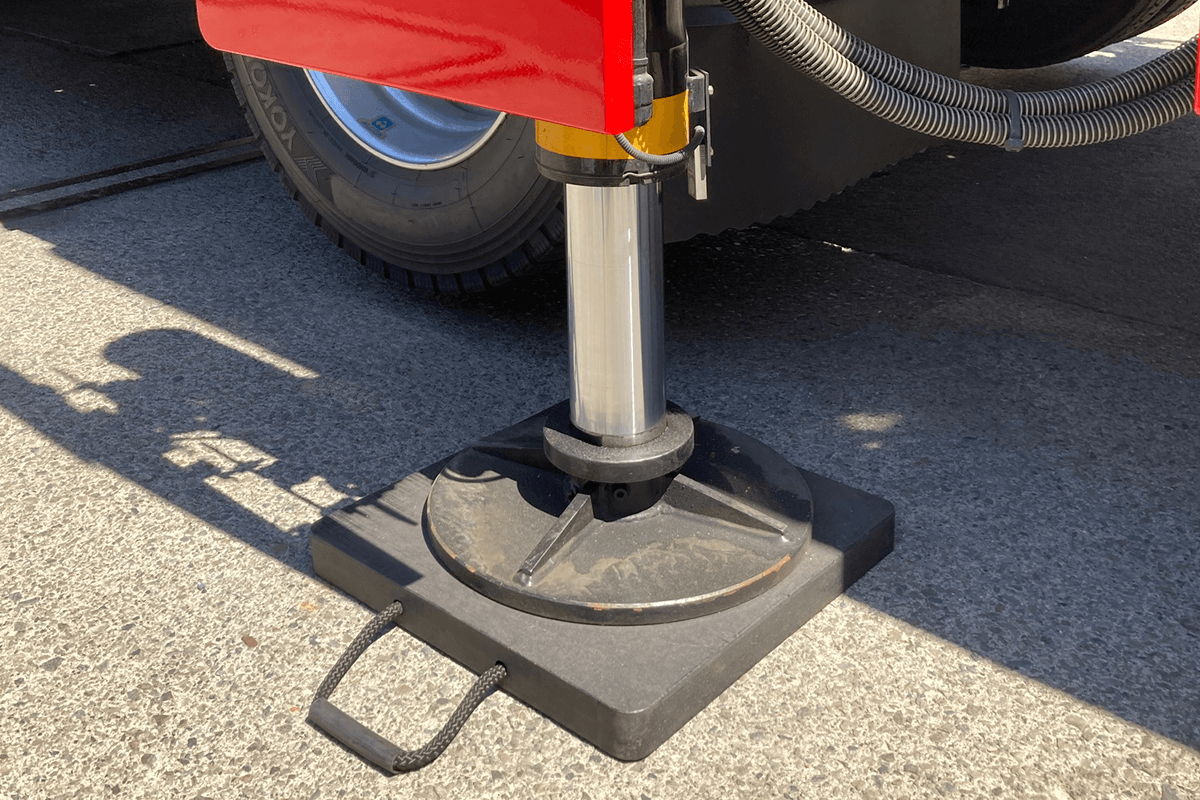

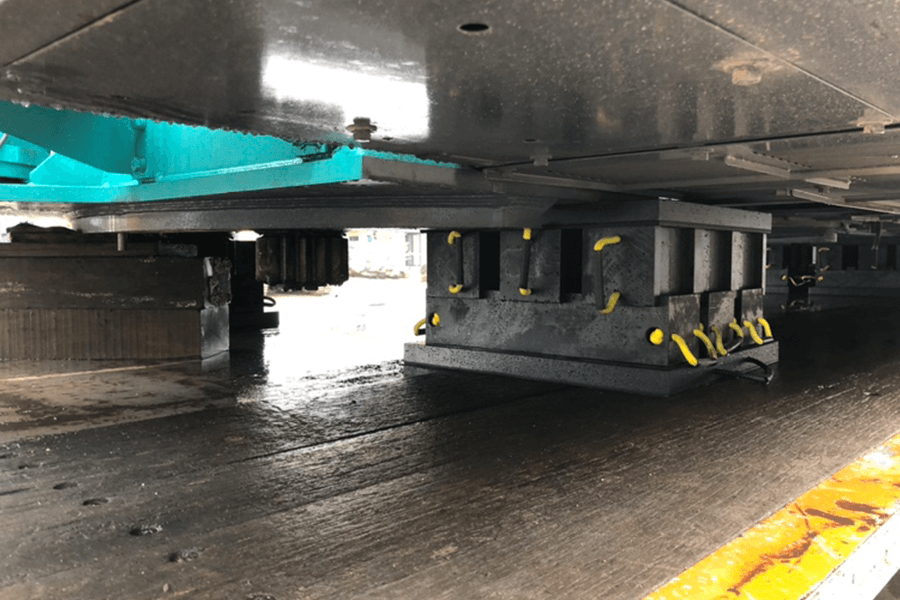

Crane pads are proven to improve machine stability and to protect expensive or sensitive flooring. When working on the ground or indoors on flooring where load bearing is an issue, make sure you use the right pads for safe lifting operations. They can also be used indoors for atrium work to prevent outrigger feet from marking the floor.

If your machinery or vehicles use stabilizers, jack legs or outriggers, we might have just the right pads for you. We cover a comprehensive product range, including competitively priced standard black pads, plus colored pads for higher visibility, as well as modular systems for mobile cranes and heavy vehicles.

Outstanding quality

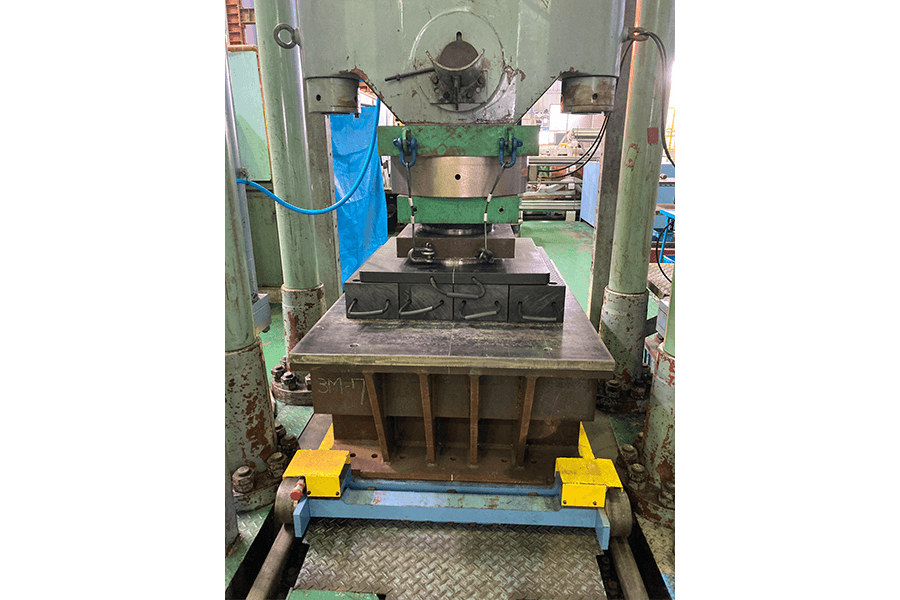

Our pads are made from high-performance polyethylene (UHMWPE), which offers significant benefits over traditional steel spreader plates or wooden pads: - Do not corrode or deteriorate, unlike wood or metal products - Are lighter weight and easier to handle than metal pads - Are chemical and water resistant for working in the harshest environments - Are UV stable, meaning they last longer than wood or metal pads - Retain their shape even under high pressure - Have rope handles, steel bar handles or integrated handles for easier lifting and shifting

The quality performance and safety of this product has been proven by quality tests conducted by an engineering consultancy and a testing company widely recognized for the field of products safety inspections in the UK. Furthermore, in Japan, quality tests have been conducted by the Japan Testing Center for Construction Materials, JFE Techno-Research Corporation and NIPPON STEEL TECHNOLOGY Co., Ltd.

Crane Pad's Product Line

You can choose from a wide range of load capabilities as well as pad types - and if you're not sure where to start, contact us for a consultation.

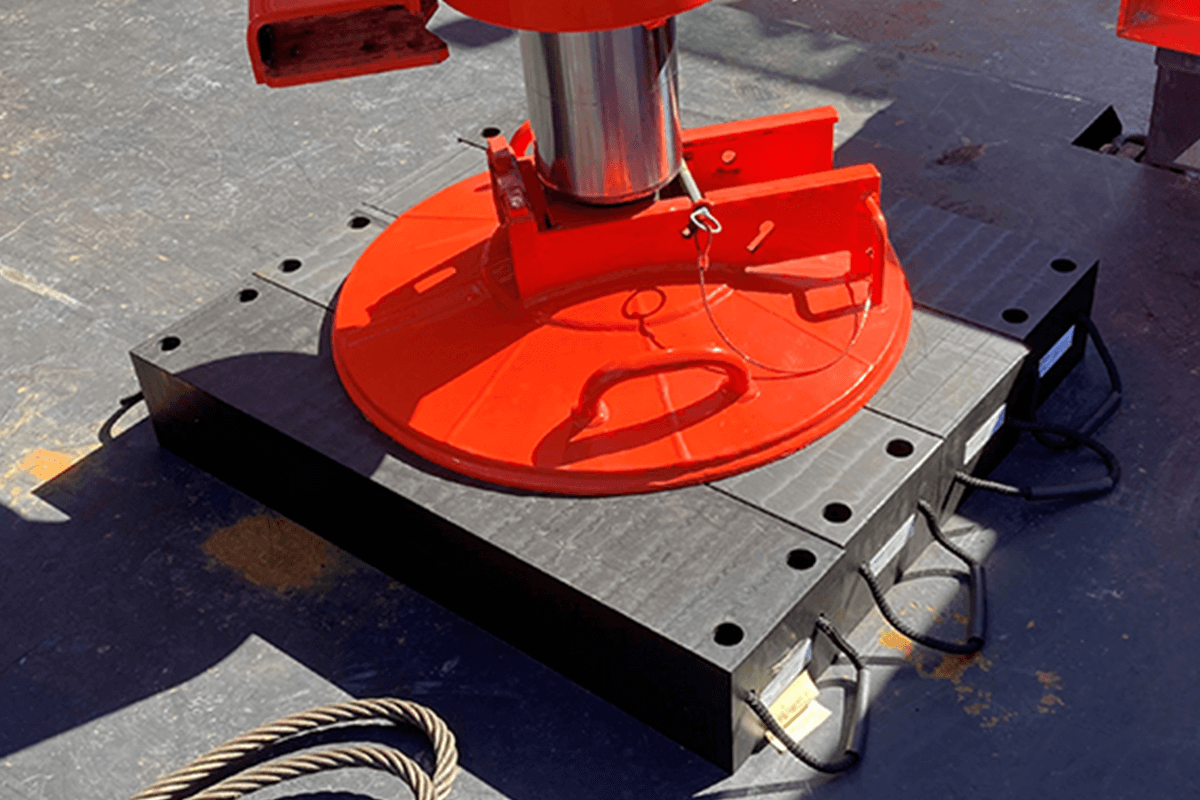

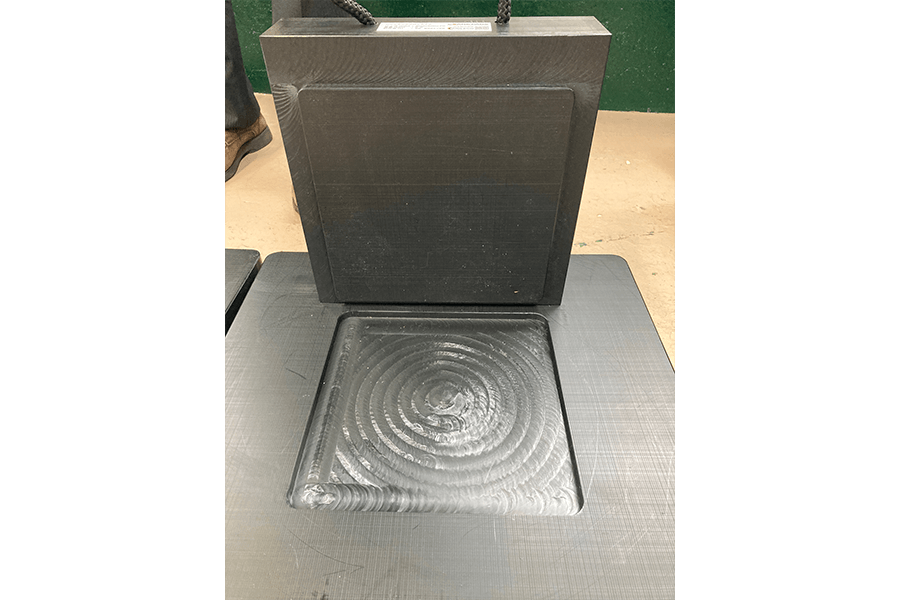

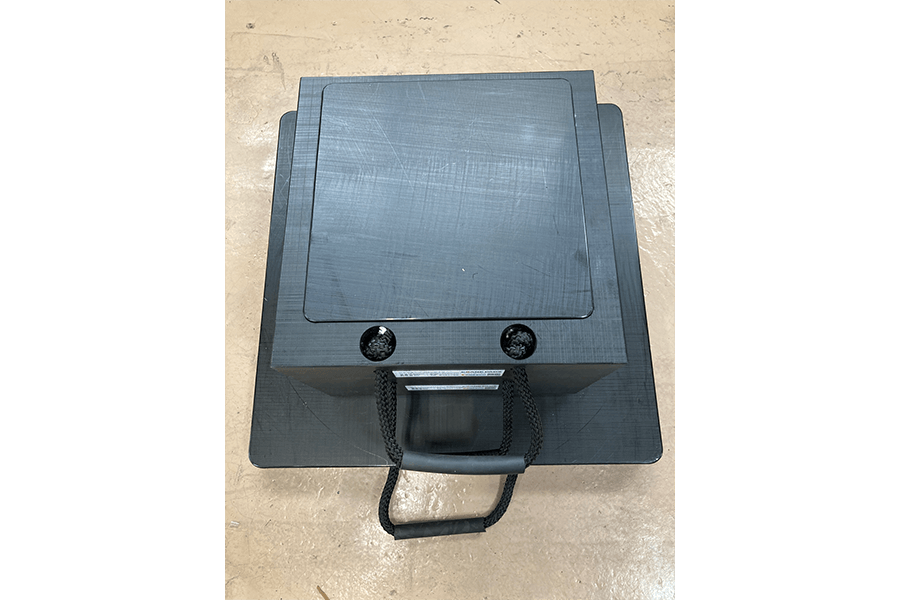

Premium Crane Pad

For a heavy duty crane, premium crane pads are essential to take the load.

Resistant to water, oil, chemicals and corrosion, these pads are great alternatives to wood, steel or aluminum spreader plates. They last longer, are easy to handle, and are inherently safer because they are almost impossible to splinter, buckle or snap.

Made from high capacity UHMWPE and with integrated rope handles,they are designed to be as easy to handle and accurately positioned as possible. The larger pads also feature a leveling indicator for extra precision.

Examples of using premium crane pads for each crane model

| 13t Rough terrain crane | ⇒ | 600 x 600 x 40 mm |

| 20t Rough terrain crane | ⇒ | 700 x 700 x 40 mm |

| 25t Rough terrain crane | ⇒ |

800 x 800 x 40 mm |

| 70t Rough terrain crane | ⇒ | 1100 x 1100 x 40 mm |

| 80t Rough terrain crane | ⇒ | 1000 x 1000 x 50 mm |

| 100t Rough terrain crane | ⇒ | 1100 x 1100 x 40 mm |

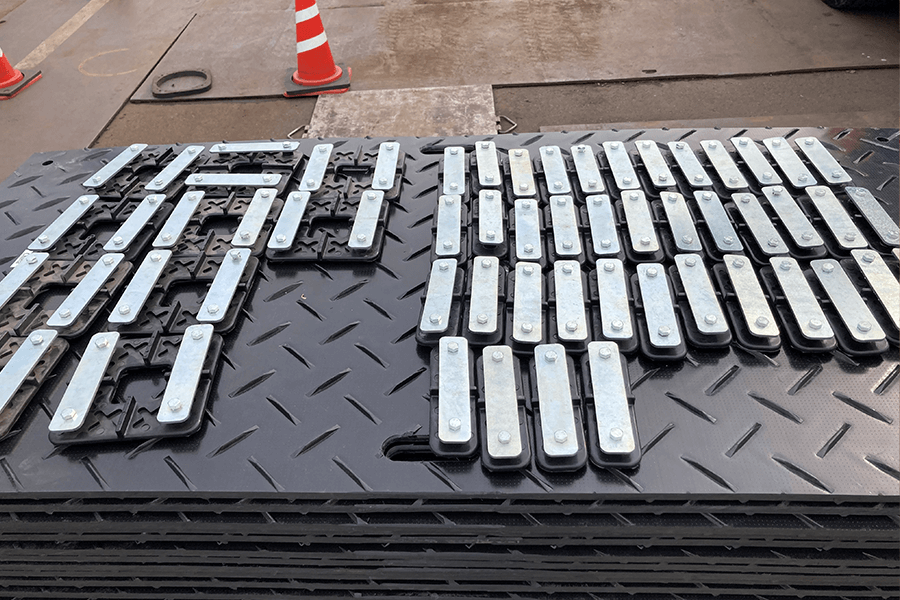

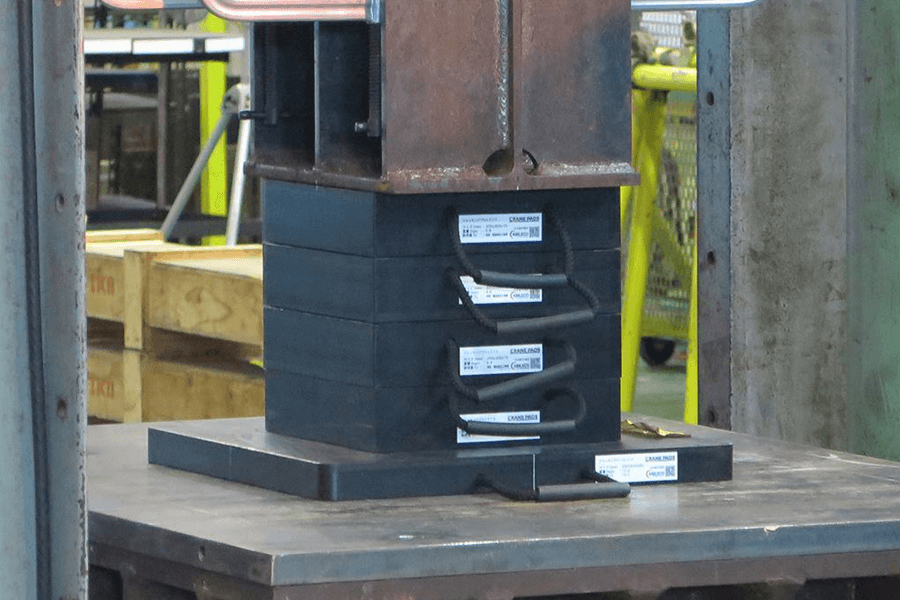

Modular Mat system

Sometimes a single crane pad is not enough. For heavy duty crane operations, you need to further spread the load - and this is where our Modular Mat systems come into their own.

Our interlocking Modular Mats enable you to essentially build bigger load spreading capabilities, and to your own configurations. These pads can be used for a variety of applications either individually or as a complete system.

Not sure which Modular Mat system you need?

Talk to our experts!

Modular Mat Setup Guide

Stage 1 - Three mats are interlocked side by side

Stage 2 - Two mats are interlocked on top at a right angle

Stage 3 - A single crane pad is placed centrally on the top, securing the Modular Mat System

アウトリガーパッドのお問い合わせ

Contact▲GROUND MATS

There are two types of mats available: extruded mats and smooth mats. Our ground mats are water and corrosion resistant, ensuring you get a durable product you can reuse again and again.

Both have been developed to handle large weight transfers while minimizing impact on the ground surface, but each has distinct material and form features.

EXTRUDED MATS

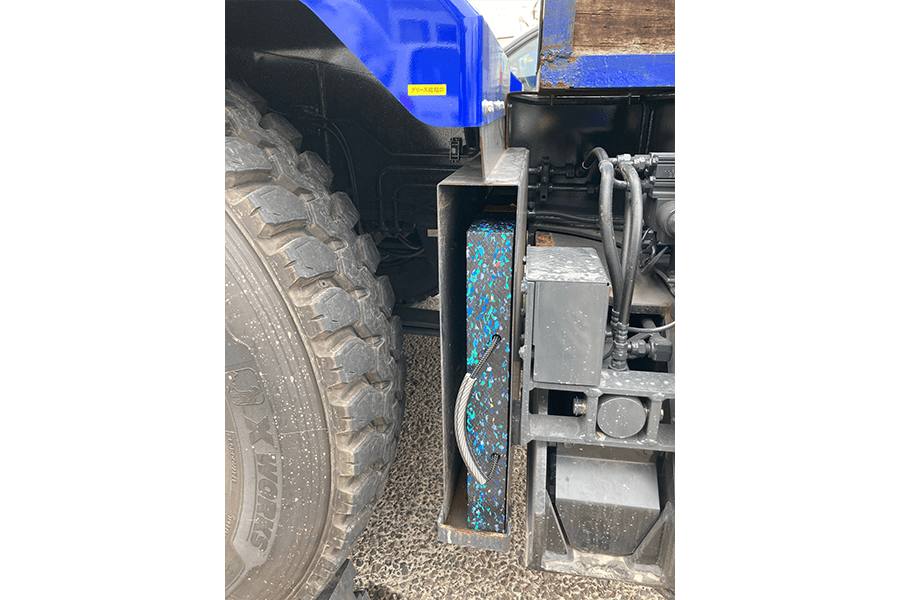

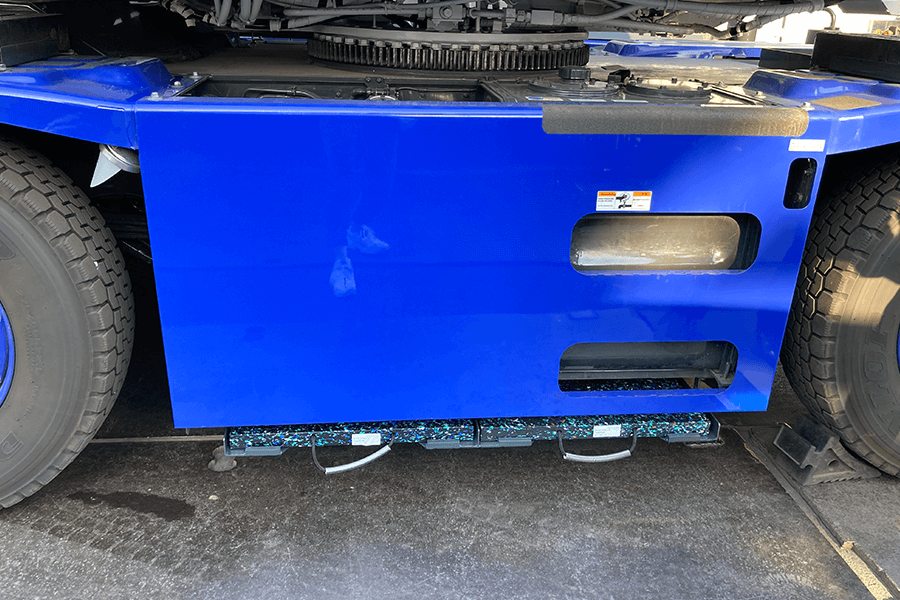

Designed with a non-slip finish on both sides, our extruded mats provide protection to the ground surface while also giving a better grip to vehicles and machinery. The mats can be connected flexibly with special connectors. Enables heavy equipment to move smoothly over common everyday bumps and unpaved ground.

Since they are made of high density polyethylene (HDPE), these mats are more flexible than smooth mats and easily accommodate to the shape of the ground.

Our connectable extruded ground mats are ideal for: - Temporary roads and walkways - Events - Construction sites - Farming and agriculture

SMOOTH MATS

Manufactured from ultra high molecular weight polyethylene (UHMW-PE), and designed with a non-slip finish on one side, our smooth mats provide protection to the ground surface while also giving a better grip to vehicles and tracked machinery.

Our smooth mats are ideal for: - Temporary roads and walkways - Events - Indoor maintenance (cathedrals & shopping centers)

Based on our extensive industry experience, these smooth mats are the ideal dimensions for use with many vehicles and tracked equipments.

SUPPORT BLOCKS

Designed for levelling heavy equipment and vehicles, our cribbing and jacking blocks are stackable, easy to handle and extremely durable. Because they don't splinter or degrade, these blocks are a much safer alternative to wood, combining high performance and a long working life. Like our crane pads, these cribbing and jacking blocks are manufactured from High Molecular Weight Polyethylene (HMWPE). Key features of this material are that it does not absorb water or chemicals, providing extra durability over wood - and it won't crack or fail like wooden alternatives.

Main applications include emergency operations such as vehicle or machinery recovery in the event of a breakdown or accident. These blocks are also ideal for shoring and carrying out maintenance on underground mining equipment eliminating the use of wood, providing axle support while carrying out routine equipment maintenance on a machine or vehicle's wheels and brakes.

Key benefits - Can be safely stacked in seconds - Lightweight and with integrated handles - Durable and long lasting - Multiple configurations - Won't crack or fail like wood can - Flexible configurations

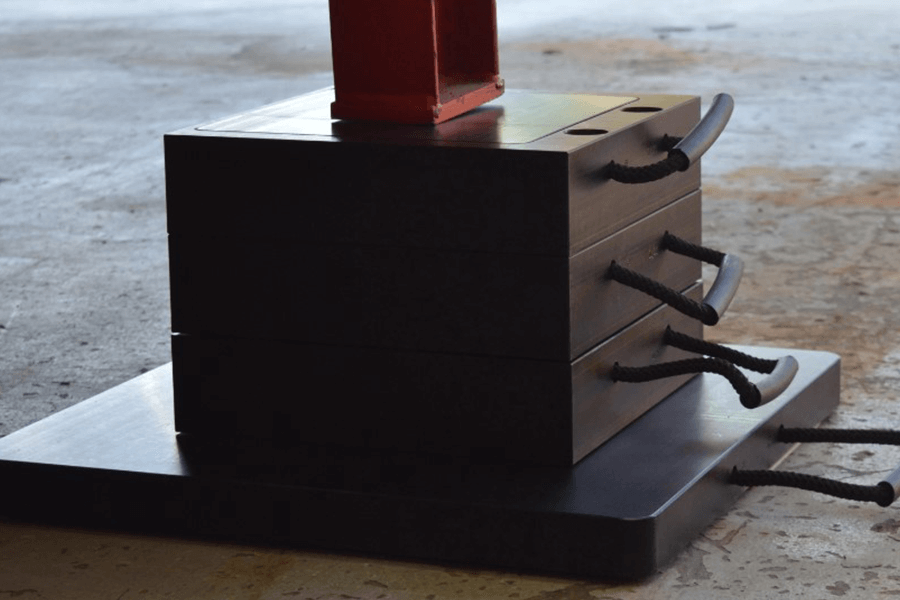

Jacking blocks

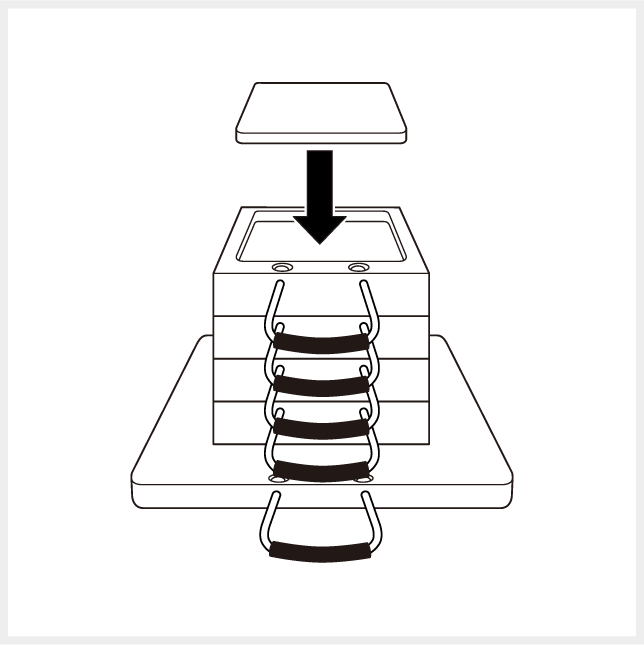

Our stackable, easily operated jacking blocks are an alternative to existing wooden blocks. They are made of high-performance materials that require minimal maintenance and have a long lasting lifetime.

The load-bearing capacity can be adjusted by stacking multiple blocks. The blocks are available in two different thicknesses, and the stacking height can be adjusted from 11 cm to 96 cm, depending on the stacking configuration. It only takes one person moving and arranging each block to create stacks of your preferable heights.

The stacking surfaces are uneven to prevent the top and bottom blocks from shifting easily when stacked.

For more details about the configuration and load capacity, please download the Configuration sheet.

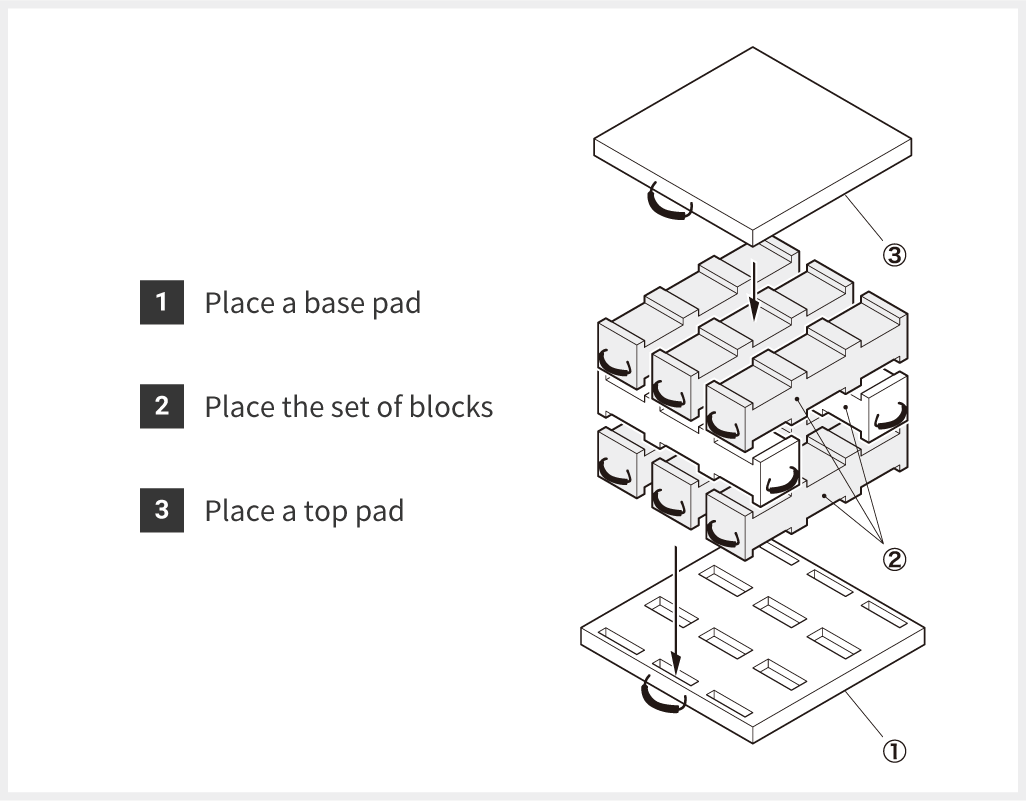

Jacking blocks setup guide

-

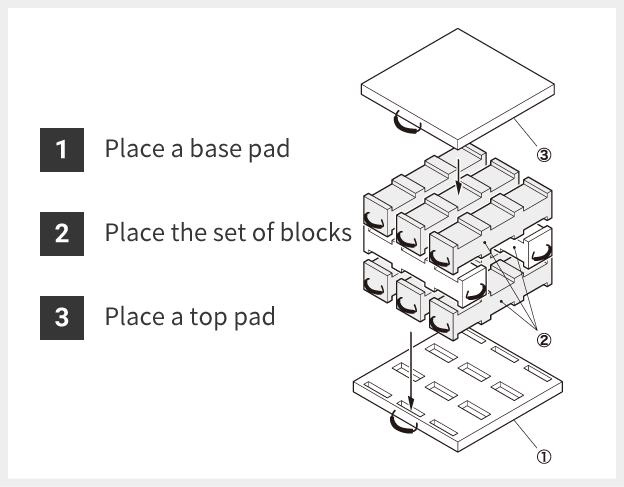

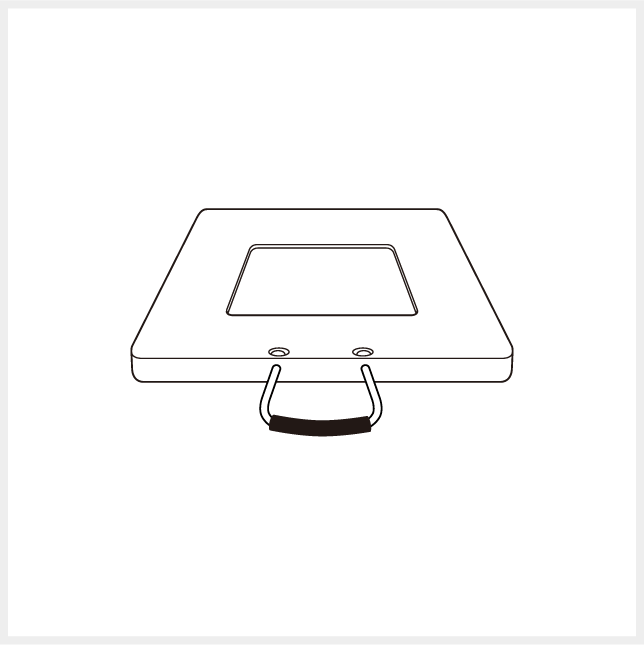

1Place a base pad

-

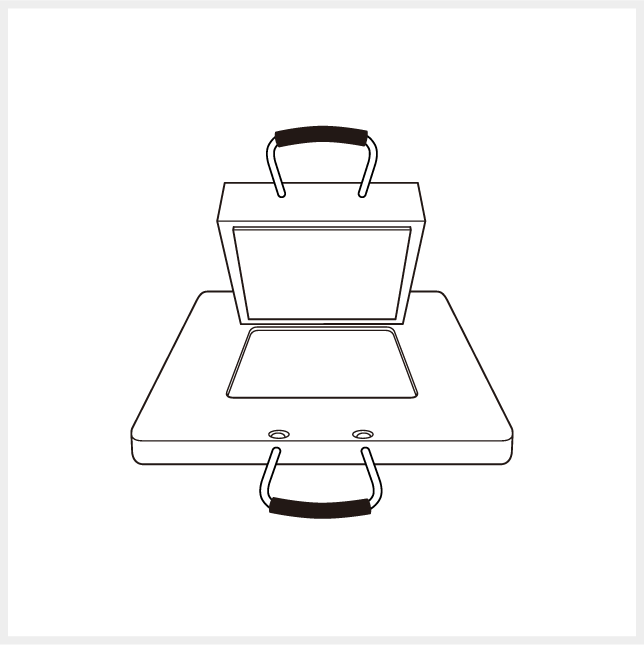

2Place the set of blocks

-

3Place a top pad

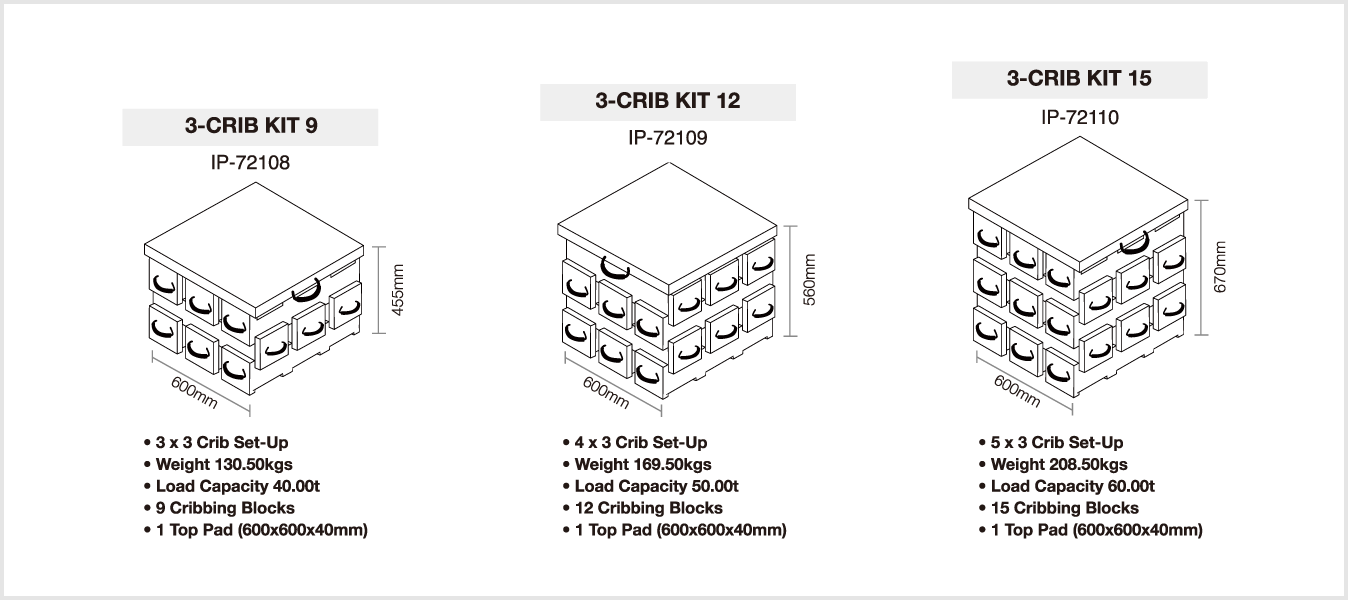

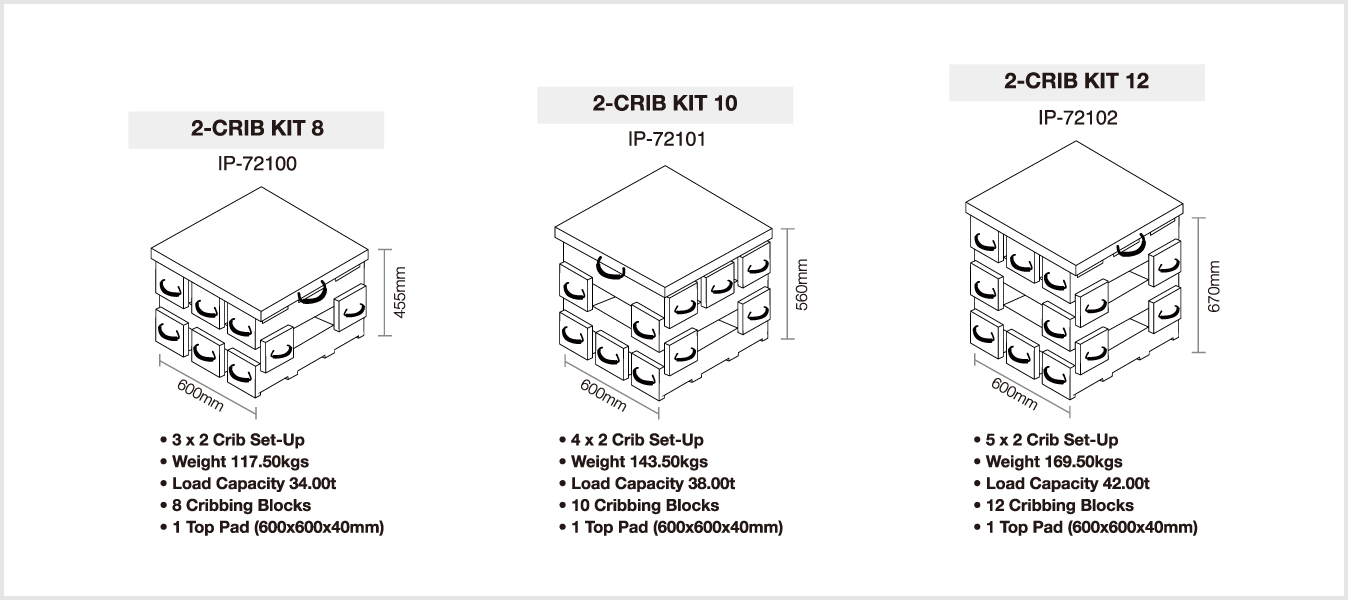

Cribbing blocks

Cribbing block provides a safe setup by stacking multiple blocks with an interlock system that will not shift or slip.

Their load capacity depends on the number of tiers in the stack and the configuration of whether the blocks are assembled with three blocks per tier or two blocks per tier.

For more details about the configuration and load capacity, please download the Configuration sheet.

Cribbing blocks setup guide

Contact

For inquiries, please call us or use the form below.